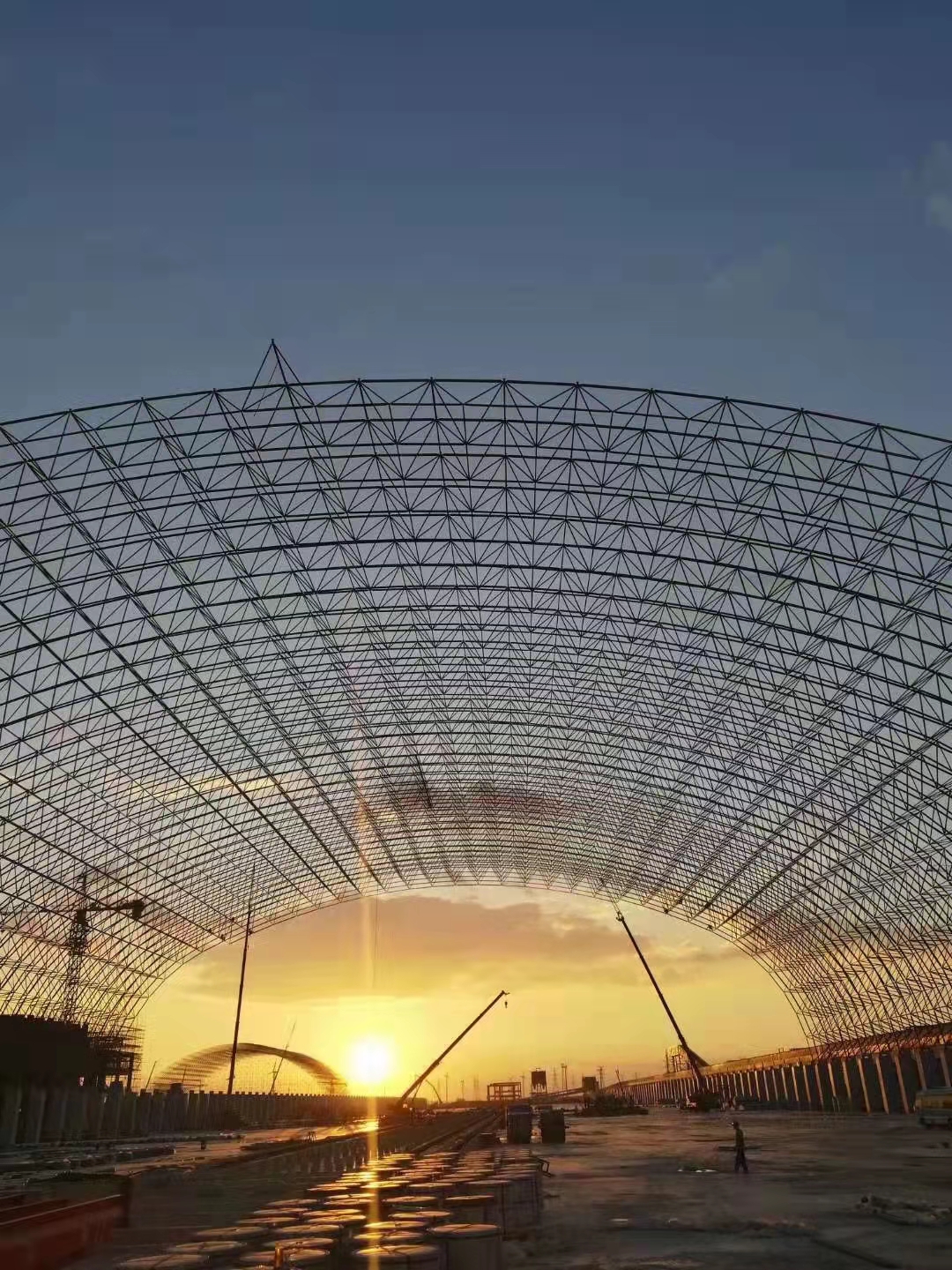

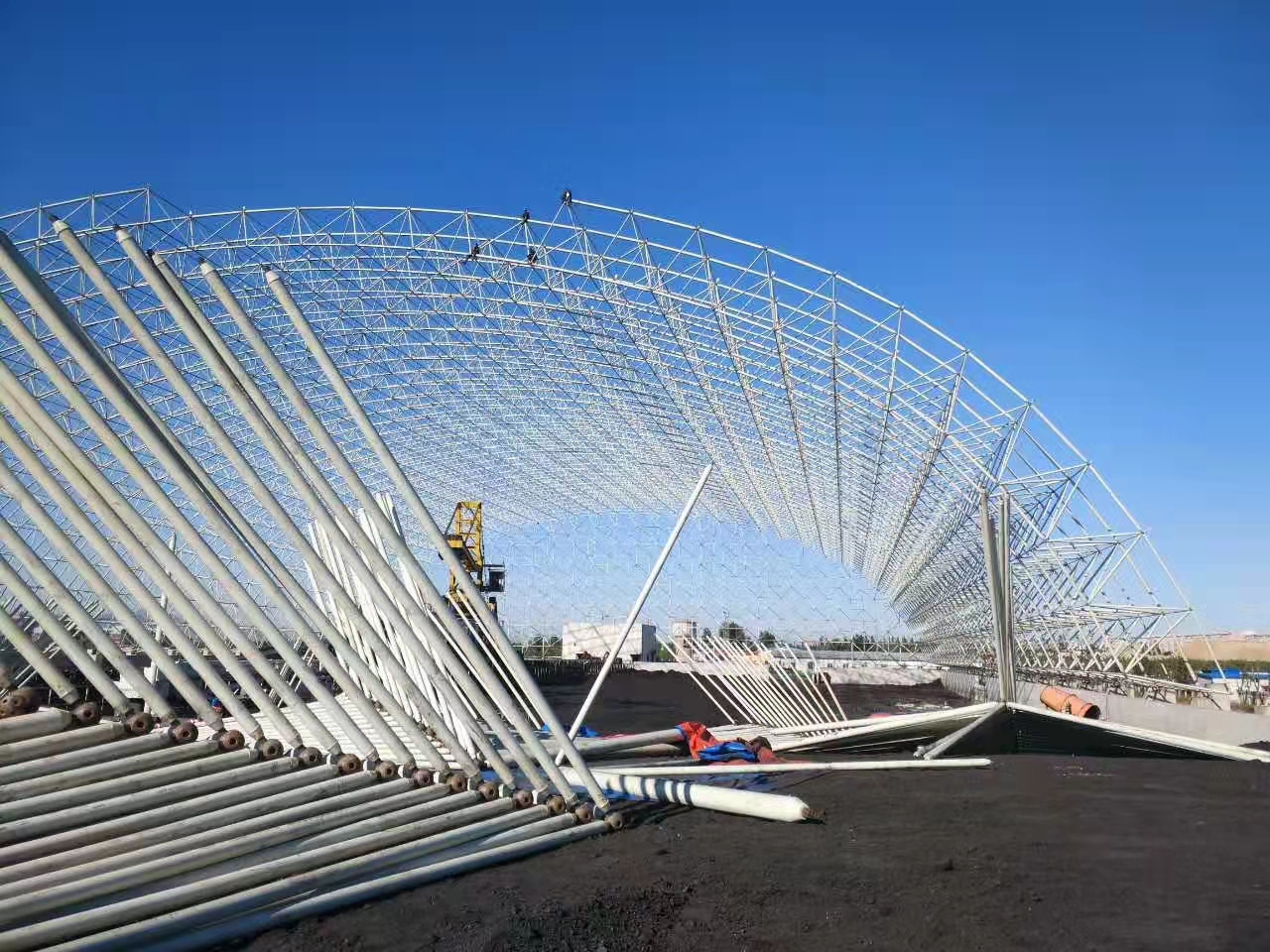

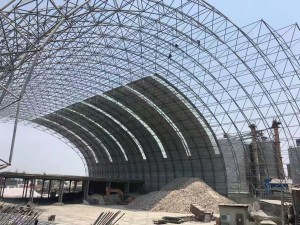

I-Ordos thermal power plant ifreyimu yesikhala yesakhiwo sensimbi eyindilinga eyindilinga

I-Raw material Q235B ipayipi elishiselwe / Ubude buphelele ngamamitha angu-49 / Ingqikithi ye-span ingamamitha angu-96 / Ubude obuphelele ngamamitha angu-567.

1. Ukukhethwa kwempahla kufanele kusekelwe kuzitifiketi zekhwalithi yokuzikhethela kanye nemibiko yokuhlolwa kabusha, ngokuhambisana namazinga kazwelonke amanje.

2. Ipayipi lensimbi lamukela insimbi ye-Q355B, ipayipi lensimbi engenamthungo noma ipayipi elishiselwe imvamisa ephezulu (GB/T 700).

3. Amabhawodi aqine kakhulu enziwe ngo-40Cr acinywa futhi aqinile futhi aphathwa ngokushisa ngokuvumelana ne- "Technical Conditions for High-Quality Carbon Structural Steel Structures" GB/T 16939. Ukusebenza kobubanzi

4. Amabhola ensimbi enziwe nge-forging yensimbi engu-No. 45 ehambisana "Nemibandela Yobuchwepheshe Yensimbi Esezingeni Eliphezulu Ye-Carbon Structural" GB 699, enamandla okukhiqiza angu-360N/mm2.

5. Ipuleti lokuvala lekhanda le-cone lenziwe ngensimbi ye-Q355B, futhi ikhanda le-cone lenziwe nge-forgings.

6. Inati elingenantambo lenziwe ngensimbi ye-Q355B yokubumba.Uma ububanzi bamabhawodi anamandla aphezulu bu> M30, sebenzisa izinsimbi zensimbi ezingama-45 gauge.

7. Izikulufo zokubopha zenziwe nge-40Cr ecishiwe futhi yaqiniswa.

8. Ukusekelwa kwenziwa ngensimbi ye-Q355B, futhi ukusekelwa kwenziwa ngensimbi ye-Q235B

9. I-electrode ithatha uchungechunge lwe-E43XX;Uchungechunge lwe-E50XX (lokushisela ibhola lebhawodi kanye nezimbambo ezithwele)

10. Ama-purlins enziwe ngensimbi emise okwe-Q235B.

11. Amabhawodi ajwayelekile enziwe ngamabholithi amaholoholo ebangeni C enziwe ngensimbi ye-Q235B ehlangabezana nezidingo zezinga likazwelonke lamanje, futhi izinga lokusebenza lingu-4.8.

12. Ama-electrodes welding kanye nezintambo ezisetshenziselwa ukushisela kufanele zihlangabezane nezidingo ezifanele zezindinganiso kazwelonke zamanje.Ukushisela phakathi kwezinsimbi ze-Q235B kusebenzisa ama-electrode ochungechunge lwe-E43, kanti ukushisela phakathi kwezinsimbi ze-Q345B kusebenzisa ama-electrode ochungechunge lwe-E50.

13. Izinto zophahla: Bheka umdwebo wesakhiwo sephaneli yegridi ukuze uthole imininingwane.

14. Ngaphezu kokuhlangabezana nezidingo zokucaciswa kwempahla kazwelonke, insimbi esetshenziswa kule phrojekthi kufanele futhi ihlangabezane nezidingo ezilandelayo:

a) Isilinganiso senani elilinganisiwe lamandla omkhiqizo wensimbi kunani elilinganiselwe lamandla e-tensile akufanele libe likhulu kuno-0.85;

b) Insimbi kufanele ibe nezinyathelo ezisobala zokukhiqiza, futhi ukuphakama kufanele kube kukhulu kunama-20%;

c) Insimbi kufanele ibe nokushisela okuhle kanye nokuqina komthelela ofanelekayo;