inqubo yokuvala uhlaka lwesikhala sensimbi

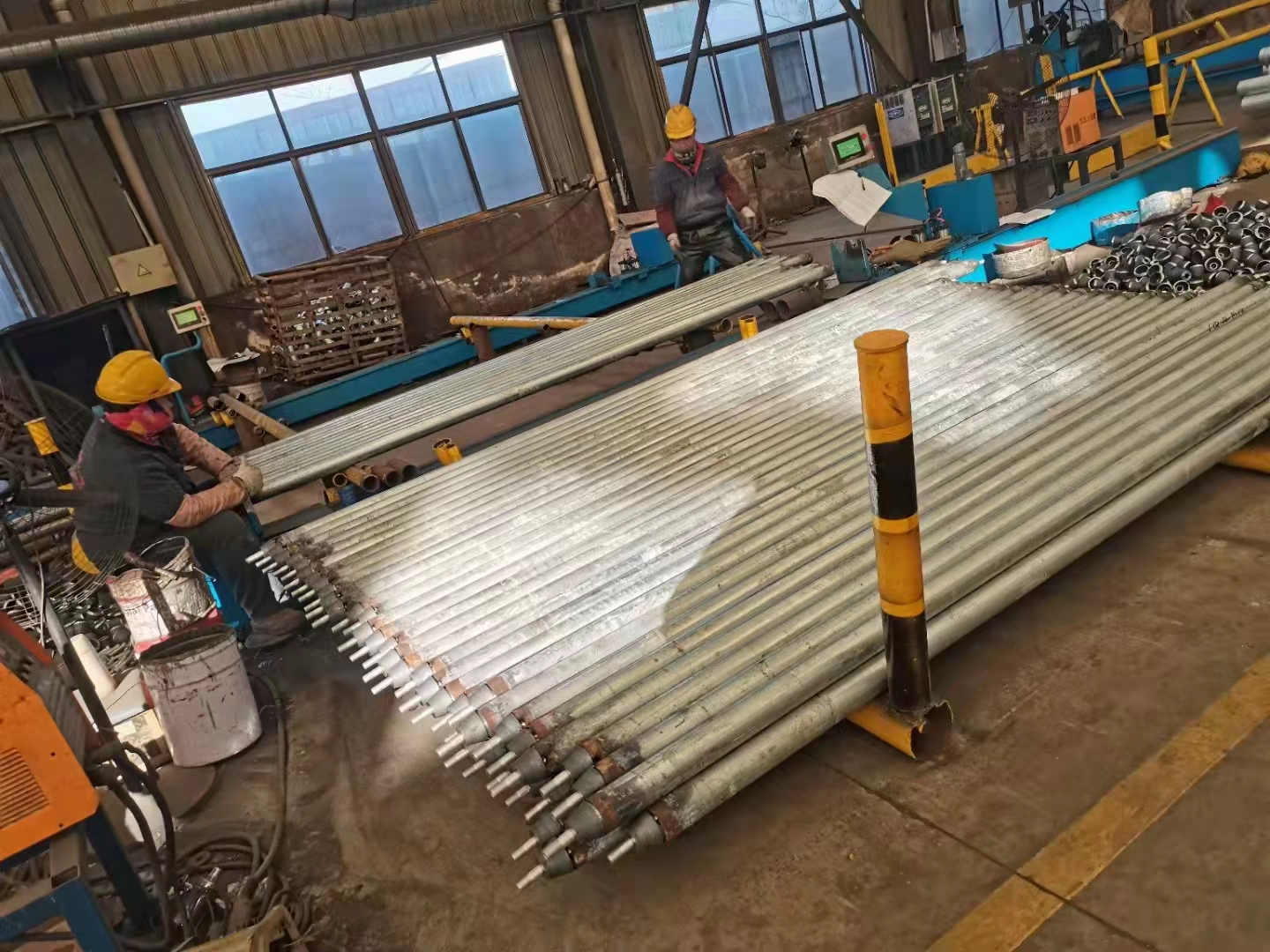

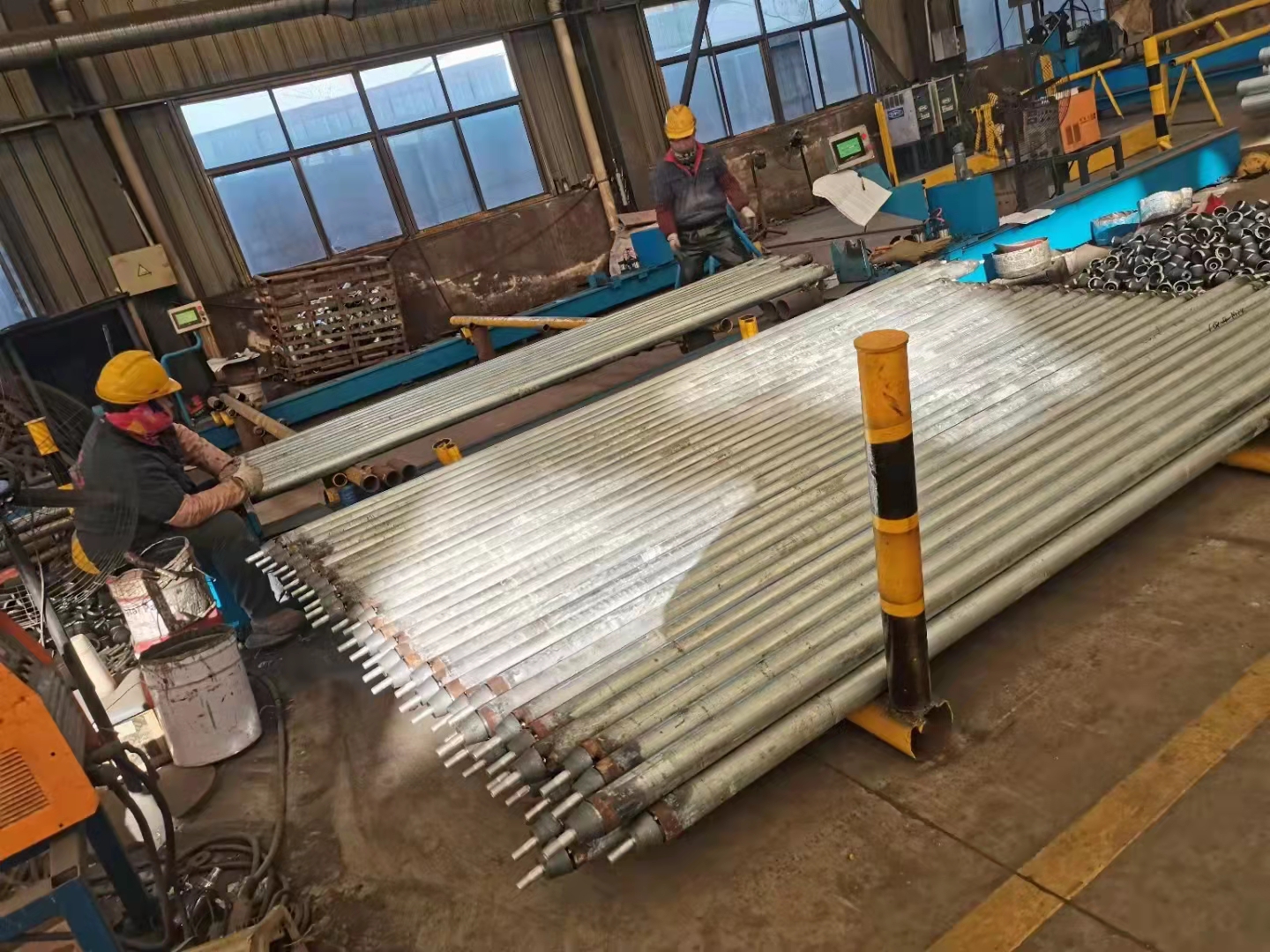

ukusika:

A.Izisebenzi zokwakha kufanele zihlole ngokucophelela imidwebo yokwakha, futhi uma kukhona izinkinga ezitholakalayo, kufanele zikhuphule ngokushesha kumuntu wezobuchwepheshe ophethe ukugwema izinkinga.

ukuxazulula inkinga ngesikhathi.

B. Ubukhulu bama-node abalulekile kufanele bukhishwe noma bubalwe.

C. Amathuluzi okulinganisa asetshenziselwa i-stakeout, ukuvala nokuhlanganisa izingxenye nokuhlola kufanele kube amathuluzi okulinganisa afanelekayo aqinisekiswe umnyango wokulinganisa nokuhlola.

D. Umugqa wokusika wokuvala kufanele ulunge futhi ucace, kube nezibonelelo zokushwabana kokushisela kanye nokucubungula onqenqemeni.

E. Ukusika izingxenye kufanele kusikwe ngomshini wokugunda, umshini wokusika amalangabi, umshini wokubhoboza ohlangene nowokugunda, umshini wokusika umnsalo, njll., kuye ngesimo esithile, futhi ukusika ngesandla kufanele kugwenywe ngangokunokwenzeka.Bheka ithebula ukuze uthole ukuchezuka okuvumelekile kwezindlela ezihlukahlukene zokusika kanye nezindawo zokusika

F. Iziteketiso zasendaweni ezinokujula okungaphezu kuka-1mm endaweni yokusika, ukusikeka ngokujula okungaphezu kuka-2mm, kanye nensalela.

Ama-burrs asele kufanele alungiswe futhi aphuculwe.

| Indlela yokusika nokuchezuka okuvumelekile kwendawo yokusika | |

| Igama lephrojekthi | Ukubekezelelana |

| Ukusika okuzenzakalelayo kanye ne-semi-automatic | ±1.5mm |

| I-non-perpendicular slope yendawo yokusika i- | ≤1.5mm |

| Ukusika i-engeli ye-bevel | ±3° |

| Ubuthuntu onqenqemeni | ±2.0mm |

| Ukusika isandla | ±2.0mm |

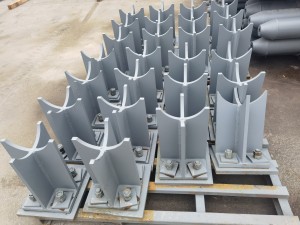

G. Ifomu le-welding groove lengxenye kufanele likhethwe ngokuvumelana nophawu lwe-welding olumakwe emdwebeni kanye nefomu le-groove nobukhulu.